Our molded nonwoven products – your benefits

✔ Excellent sound absorption – effective noise reduction and vibration damping

✔ Excellent thermal insulation – improves the energy efficiency of your systems

✔ Tailored shapes – Perfectly adapted to demanding component geometries

✔ Lightweight & sustainable – resource-saving materials with low weight

✔ High robustness – Resistant to moisture, oil, etc.

✔ Flexible production – manufacturing process for small batch and series production

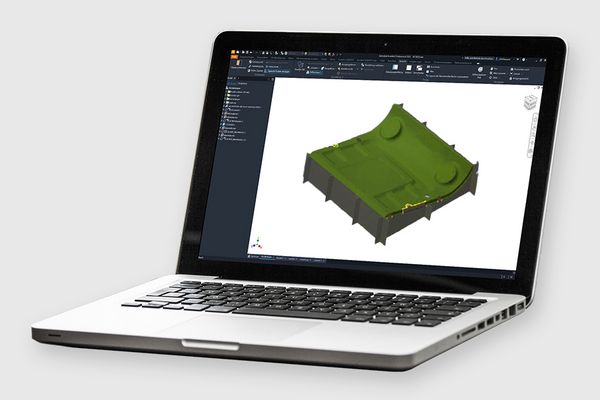

✔ Support in the creation of the design, including feasibility analysis

✔ Wide variety of materials – for noise control in combination with tech solutions

✔ On-site consultation – for an ideal fit to your vehicle

✔ Ready-to-install – for quick and easy integration

Ready-to-install soundproofing and insulation solutions for vehicles and machines

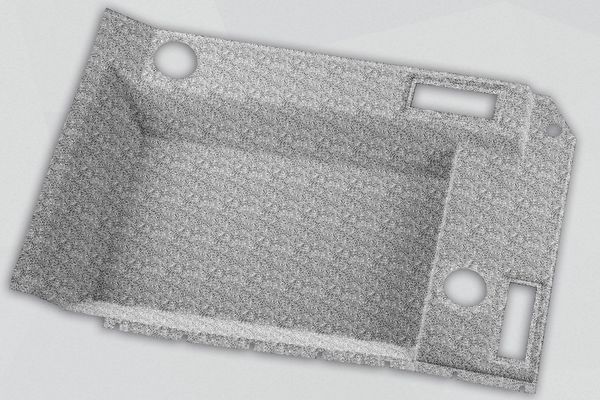

Molded non-woven products are the perfect choice for effective sound and heat insulation in technical applications. Cellofoam develops and produces high-quality molded non-woven products that can be adapted optimally to complex geometries and are used in vehicles, machines and industrial applications.

Customized interior parts for the highest requirements

In our non-woven molding processes, state-of-the-art machines and presses turn the non-wovens into dimensionally stable, self-supporting, two- and three-dimensional parts according to customer specifications. The resulting products score with their excellent acoustic effectiveness and high dimensional stability.

Innovative production & sustainable combination materials

We match and combine various materials to create targeted solutions for different surface requirements and applications. Our non-woven products are based on high-quality polyester fibers (PES) and are partly made from recycled materials. Innovative production techniques such as thermomolding, water jet cutting and punching, enable us to realize tailor-made solutions for a wide range of sectors.

Get in touch now & discover tailored solutions!

Molded non-woven parts from Cellofoam are used as

✔ Cabin lining – reduces noise and improves the indoor climate

✔ Head liners – light and robust lining with optimum sound absorption effectiveness

✔ Side panel liners – functional and aesthetic solutions for interiors

✔ Rear wall cladding – optimizes the interior acoustics and reduces droning

✔ Beam cladding - acoustically optimized for load-bearing body structures

✔ Technical covers – dimensionally stable elements for machines & vehicles

✔ Engine compartment liners – heat-resistant and sound-absorbing

✔ Hood covers – combine thermal insulation with sound absorption

Processing technologies

- Fully automated thermomolding production line

- Hot pressing and cold pressing for thermoplastic materials

- 70- to 400-ton presses

- Two- and three-dimensional parts up to a size of 1900 x 2100 x 400 mm

Depending on the material, the batch size and the geometry of the parts, we use different, optimally matched production methods and tools. In this way, we ensure that every solution convinces on both the technical and the economic level.

Materials

- Various non-wovens made from viscose or polyester fibers

- Mixed-fiber non-wovens

- Wide range of visually attractive facing materials, for instance:

- Decorative non-woven with excellent technical properties (washable, oil- and water-repellent, resistant to high-pressure cleaning)

- Mechanically robust needled felts

- Various knitted fabrics with high elasticity for perfect adaptation to surface contours

- Heat-reflecting aluminum films and foils

Optional: Customer-specific facing materials on request.

Typical uses