About us

Cellofoam develops and produces high-quality sound insulation and sound damping products as well as sealing products for a wide range of industrial and technical uses.

We supply a wide range of ready-to-install products optimized for acoustic effectiveness. We process predominantly high-quality flexible foams and non-wovens (PUR, PE, PP PES, fiber blends), using proprietary and patented processes.

We are particularly proud of our special Cello® process for foam finishing, which enables us to produce top-quality absorber foams. Another very important asset is our expertise regarding various laminating techniques for the production of many different, acoustically engineered combination products.

Ever since its foundation in 1963, Cellofoam has been one of the leading experts for lamination, developing and using flame and dry-adhesive lamination techniques.

Another specialty of Cellofoam are applications involving non-wovens, which we turn into dimensionally stable, two- and three-dimensional parts.

Our portfolio is rounded out by the product areas of pipe insulation, adhesive tapes, vibration insulation, compressor jackets, and various products for improving room acoustics.

Download company info

Expertise in acoustics

In our in-company reverberation chamber, we can perform acoustic measurements on noise absorber materials of any structure, entire 3D parts, sound-absorbing wall/ceiling panels or partition walls and much more. Besides impedance tube tests, this is another excellent tool for us to provide our customers with data-based recommendations for the optimum acoustic solution.

Comprehensive sound measurements carried out by our experienced specialists at the customer’s site are the best option when the objective is to integrate the necessary noise control measures from the start and avoid the need for subsequent rework to comply with noise regulations.

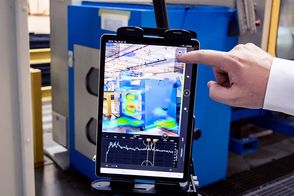

With the purchase of our new acoustic camera, our experts can now visualize the noise problem on site and precisely identify any problematic areas. Feel free to ask us for more information.

Factory equipment

- Equipment for foam finishing (Cello® process)

- Equipment for the molding and densifying of foams, laminated materials and non-wovens

- 3D-contour cutting equipment and water-jet cutting machines

- Cutting and die-cutting equipment

- Variety of precision tools etc.

- Flame treatment machine for processing parts made from EPP

- Laboratory with comprehensive instrumentation for mechanical, acoustical and fire-safety tests

- Reverberation room for acoustic measurements

- Special technique for sealing all faces of cut-to-measure pieces with film

- Processing units for flame and dry-adhesive lamination

- Cutting and die-cutting equipment, especially for adhesive and sealing tapes

- Impregnation system for soft foams

Our products and services

- High-quality sound insulation and attenuation products made from acoustically highly effective foams and non-wovens

- Parts can be assembled in sets and packaged to suit your operations requirements

- Extensive expertise of our acoustics specialists combined with detailed knowledge of the requirements that our materials will have to meet in the end customer’s applications (e.g. fire safety)

- On-site acoustic measurements and consulting services offered free of charge by our experienced specialists

- High-quality gaskets and seals

- Vibration dampers for preventing the propagation of solid-born noise

- Pipe insulation materials for protection and thermal insulation of pipes and ducts

- Matching adhesive tapes for sealing edges, joints and seams of pipes

- Development of customer-specific products and solutions

- Fast quote preparation and order processing

- Short delivery times