Sound absorber

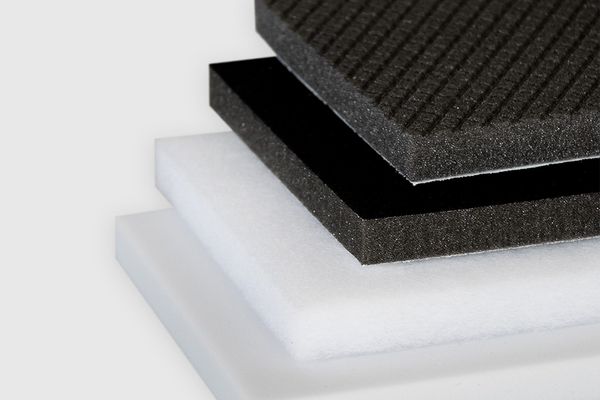

Sound absorbers are materials that absorb sound waves and convert their energy into heat. They are used to improve acoustics. Sound absorbers are available in a variety of base materials, surface textures and thicknesses.

The degree of sound absorption of a material is indicated by its absorption coefficient. This makes it easier to compare different products with each other.

In technical applications, sound absorbers are used wherever disturbing noises need to be reduced and the acoustic environment optimised – for example, in machine rooms, vehicle cabins, heat pump housings or in the room acoustics of production and laboratory areas. Their targeted selection and placement contributes significantly to improving working conditions, product quality and energy efficiency.

Cellofoam's portfolio of sound absorbers

1. Absorber foams

Cellofoam develops and manufactures ready-to-install sound insulation solutions based on soft foams. These open-cell or semi-open-cell PUR and PE foams are characterised by high sound absorption values and are used in areas such as mechanical engineering, automotive engineering and building services engineering.

2. Moulded non-woven fabrics

In addition to foams, the range also includes dimensionally stable, sound-absorbing non-woven fabrics. These are usually made of polyester fibres (PES) and offer effective sound absorption combined with low weight. They are particularly suitable for use in vehicle cabins, heat pump housings or partition walls.

3. Heavy-duty films (bitumen/plastic)

Cellofoam also offers heavy foils – such as bitumen or plastic heavy foils – for combining sound absorption and sound insulation. These are often used in sandwich constructions with absorber foams to reduce both airborne and structure-borne noise.

4. Customised solutions

Cellofoam also offers individually tailored sound absorber panels and modules, e.g. for mobile absorber walls or special housing constructions.

5. Sustainable materials

Recycled materials are also used in many projects – such as sound absorbers made from PES nonwovens – underlining the commitment to sustainable product development.