Noise abatement – Effective sound insulation for machines, vehicles and buses

Noise abatement is an essential part of technical sound insulation, especially in mechanical engineering, automotive engineering and the sound insulation of buses and rail vehicles. Noise in industrial applications or in transport can not only worsen working conditions, but also shorten the service life of machines and impair driving quality.

Noise protection also plays a central role in the construction and agricultural machinery sector:

Manufacturers of excavators, wheel loaders and tractors must comply with strict EU limits for noise emissions. This requires the encapsulation of engines and hydraulic systems as well as the acoustic optimisation of driver cabins – for example, through absorbent cladding and insulation mats on cladding panels. In addition, workplace limits of a maximum of 87 dB(A) apply, which necessitates soundproof cabins and low-noise designs.

Cellofoam offers tailor-made noise control solutions to minimise sound transmission and reduce acoustic stress in industrial and mobile applications.

How is noise generated in machines and vehicles?

Noise in technical areas is generated by various sound sources that propagate via airborne and structure-borne sound:

- Machine noise and production facilities – motors, pumps, fans and presses generate high levels of noise pollution

- Vehicle noise and bus acoustics – chassis noise, engine vibrations and wind noise

- Rail vehicles – rolling noise, brake squeal and drive noise, which propagate via the chassis, car body and interior, affecting both passengers and staff

- Structure-borne noise and vibrations – sound waves that spread through solid components and generate disturbing resonances

- Airborne noise – direct sound transmission, e.g. from loud machines or passenger areas

Targeted sound insulation measures must be taken to combat noise in the long term.

Cellofoam soundproofing solutions for noise reduction

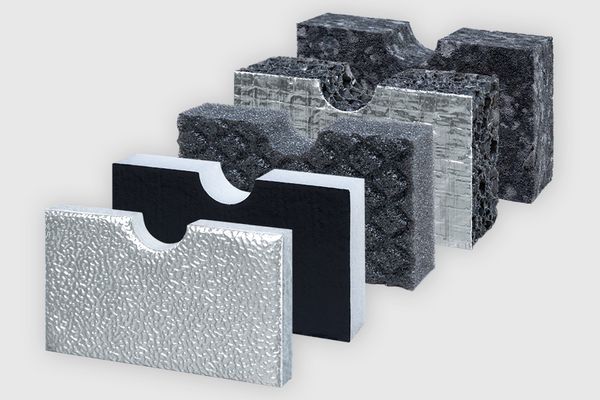

Our high-quality sound insulation materials effectively reduce noise in machines, vehicles and buses:

✔ Acoustic foams & sound absorbers – Reduce airborne noise & improve room acoustics

in machine rooms & driver's cabs

✔ Heavy bitumen foils & heavy plastic foils – Dampen low-frequency noises & vibrations

in chassis & car bodies

✔ Structure-borne sound insulation – minimises sound transmission through vehicle

frames, machine housings and panelling

✔ Customised noise protection solutions – tailor-made products for specific applications

in industry and transport

Areas of application for noise abatement

- Vehicle technology & buses – reduction of engine, transmission and chassis noise for greater driving comfort

- Mechanical engineering & industry – sound insulation for production halls, technical enclosures and workplaces

- Rail vehicles – noise protection for passenger areas, engines and air conditioning systems

- HVAC & heat pumps – noise reduction in ventilation systems & industrial air conditioning units

Why is noise abatement important?

✔ Improved working conditions – reduced noise increases concentration and safety

✔ Increased product quality – less noise means greater driving and working comfort

✔ Compliance with legal requirements – reduction of noise emissions in accordance with noise protection guidelines

✔ Health protection – minimisation of noise pollution, hearing damage and stress factors

Conclusion

Effective noise abatement in machines, construction and agricultural machinery, rail vehicles and buses not only improves comfort, but also contributes to the longevity of technical systems. Cellofoam develops highly effective sound insulation solutions to reduce noise in a targeted manner and minimise acoustic pollution.

✉ Contact us for tailor-made noise control solutions!