Efficient noise reduction

Customized applications in industry and technical contexts

Noise is everywhere – in vehicles, machines, and buildings. But we are convinced that Peace and quiet are essential for a high quality of life. This is precisely why we at Cellofoam work every day to make the world a little quieter.

As a family business that puts its heart and mind into responsible business operation, we have been developing and producing clever solutions for noise control, thermal insulation and sealing for over 60 years – with passion, precision and an eye for the essentials. Our materials are put to good use wherever people live, travel or work and need to feel comfortable – in homes and offices, buses, trains and construction machinery, in heat pumps, noisy appliances, production halls or kindergartens.

Quieter doesn't just mean more pleasant – it also means more sustainable. Our products not only help reduce noise, but also actively contribute to environmental protection – through energy-efficient insulation, durable materials and a resource-saving manufacturing process. Already today, many of our non-wovens are made largely from recycled material: another step towards the future.

What makes Cellofoam special? We are a team. Down-to-earth, solution-oriented, dependable and with a mindset that fosters true cooperation – inside the company and with suppliers and customers alike. Our customers appreciate not only our products, but also our openness, our experience – and our genuine interest in long-term partnerships.

Cellofoam – more than just a name.

Our brand stands for the promise of creating a quieter, more livable world through customer-oriented service, the use of state-of-the-art technology, and in-depth technical expertise.

Download here our company information

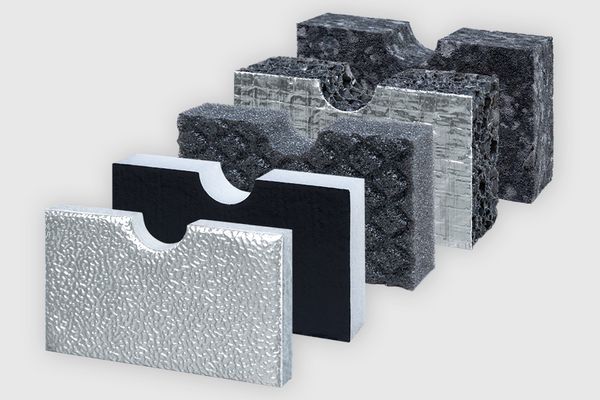

✔ Acoustic foams and PES non-wovens

✔ High-quality gaskets and flat gaskets

✔ Vibration dampers for the attenuation of solid-born noise

✔ Pipe insulation materials for thermal insulation and protection of pipes and tubes

✔ Adhesive tapes for masking edges and sealing pipes

✔ Room acoustics solutions for projects of all kinds and sizes

✔ Compressor jackets for HVAC systems & heat pumps

✔ Bitumen-based and synthetic heavy layers

✔ Molded non-woven parts precisely tailored to your requirements

✔ Products laminated with different surfaces

✔ High-quality sound insulation and attenuation products made from acoustically highly effective foams and non-wovens

✔ Parts can be assembled in sets and packaged to suit your operational requirements

✔ Knowledge of the application conditions for the material (e.g. fire safety requirements)

✔ Acoustic expertise, acoustic measurements and on-site consultations

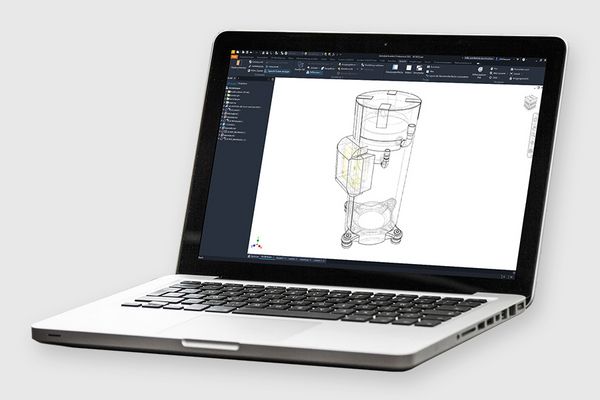

✔ (Technical) solutions designed in close cooperation with the customer

✔ Development of customer-specific products and solutions

✔ Fast quote preparation and order processing

✔ Short delivery times

Our in-house reverberation chamber enables the Cellofoam experts to precisely measure a wide variety of acoustically effective materials under realistic conditions. Whether sound absorbers with a structured surface, customized molded parts, sound-absorbing wall and ceiling elements, or room dividers – all products can be analyzed and evaluated in terms of their sound absorption efficiency as per the applicable technical standards.

In addition, we use the impedance tube to study the acoustic behavior of various materials under controlled conditions. The combination of both measurement methods allows us to provide fact-based and targeted product recommendations tailored to your application – functional and effective.

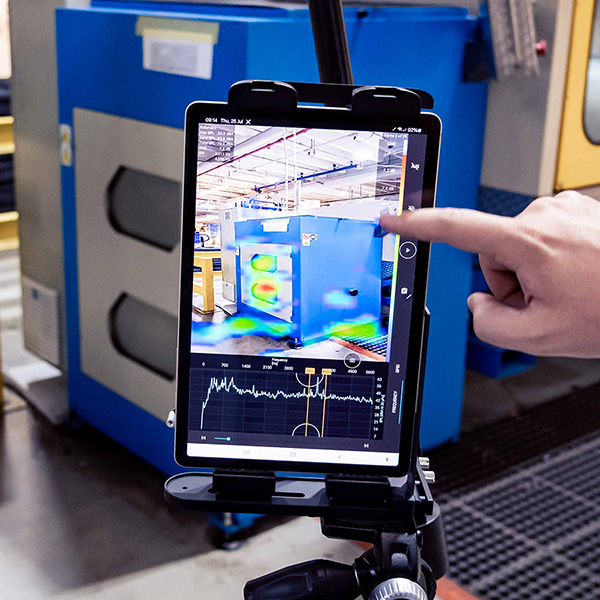

For complex applications, we can also carry out acoustic measurements directly on your premises. Our experienced acoustics specialists rely on their in-depth specialist knowledge and state-of-the-art equipment to analyze your specific noise challenge. This makes it possible to precisely pinpoint critical noise sources and design suitable measures already during the design or planning phase – and prevent the need for later redesign and reworking of your product.

A special highlight: our acoustic camera. This leading-edge technology allows us to make noise visible. The visual representation enables the precise localization of noise sources and the clear identification of the causes of unpleasant sounds – an invaluable basis for the development of targeted noise-control solutions.

Would you like to know where the noise is coming from? We will be happy to support you – efficiently, visually and on site.

Why not ask our experts for advice right now!

✔ Equipment for foam finishing (Cello® process)

✔ Equipment for the molding and densifying of foams, laminated materials and non-wovens

✔ 3D-contour cutting equipment and water-jet cutting machines

✔ Cutting and die-cutting equipment

✔ Variety of tools for precision cutting

✔ Flame treatment machine for processing parts made from EPP

✔ Laboratory with comprehensive instrumentation for mechanical, acoustical and fire-safety tests

✔ Reverberation chamber for acoustic measurements

✔ Special process for sealing all faces of cut-to-measure pieces with an impermeable film

✔ Processing units for flame and dry-adhesive lamination

✔ Special cutting and die-cutting equipment for adhesive and sealing tapes

✔ Impregnation system for soft foams

For the rail vehicle industry we offer:

In the area of buses and commercial vehicles we provide:

Our solutions for construction, forestry and agricultural machinery include:

For heating, ventilation and air-conditioning systems, we offer:

In the area of medical technology we support:

In the mechanical engineering industry we deliver:

For the room acoustic inside buildings we provide:

Also for yachts and motorboats we offer ideal solutions:

You can put your trust in our more than 60 years of experience and innovation in the field of sound insulation and attenuation. Together with you, Cellofoam will address your acoustic challenges and define the right product(s). Contact us today to find out how our tailor-made solutions can optimize your industrial applications.

Cellofoam – We make the world a quieter place